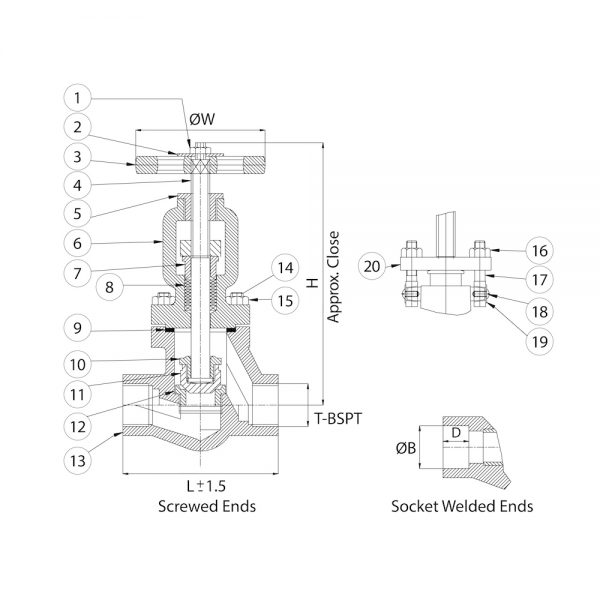

Description

- NETA Forged Steel Class-800 Globe Valve (Reduced Bore) to BS:5352 / API 602

- Bolted Bonnet

- Outside Screw and Yoke Type

- Rising Stem 13% Cr. S.S. (AISI-410) Trim

- Screwed Female (BSPT, NPT, API) or Socket Welded Ends conforming to ASME B 16.11.

Test Pressure

Body : 3000 PSIG Hydrostatic

Seat : 2000 PSIG Hydrostatic, 100 PSIG Air

Backseat : 2000 PSIG Hydrostatic

Design Features

- Streamlined shaped flow way area for smooth flow of the working fluid for minimum pressure drop.

- Bolted Body Bonnet Joint.

- Renewable 13% Cr. S.S. (AISI-410) Body Seat Rings and Wedge having difference in hardness of at least 50 HB.

- S.S (AISI-304) Spiral Wound Asbestos filled Gasket for Body Bonnet Joint.

- Designed for tight shut off and efficient fluid control.

- Ample depth of stuffing box in Globe Valves.

- Bolted self aligning two piece Gland in Globe Valves.

- The provision of back seating arrangement in Globe Valves permit replacement of Gland packing in fully open position while the Valve is under in line pressure.

- Self aligning loose regulating Valve disc on stem in Globe Valves.

- Sturdy spoked hand wheel is provided for operation in Globe Valves.

- Globe Valves have a Tee-head stem connection for maximum dependability. Stems are provided with outside acme threading which do not come in contact with the process fluid & can be Lubricated easily.

Certification

IBR Test Certificate in Form III-C duly signed by the Director of Boilers, Punjab is provided for Valves to be used for steam service. For service other than steam our Works Test Certificate shall be provided.

Application

Steam, Water, Oil

HSN

84818010